DROP TEST RIG

2021

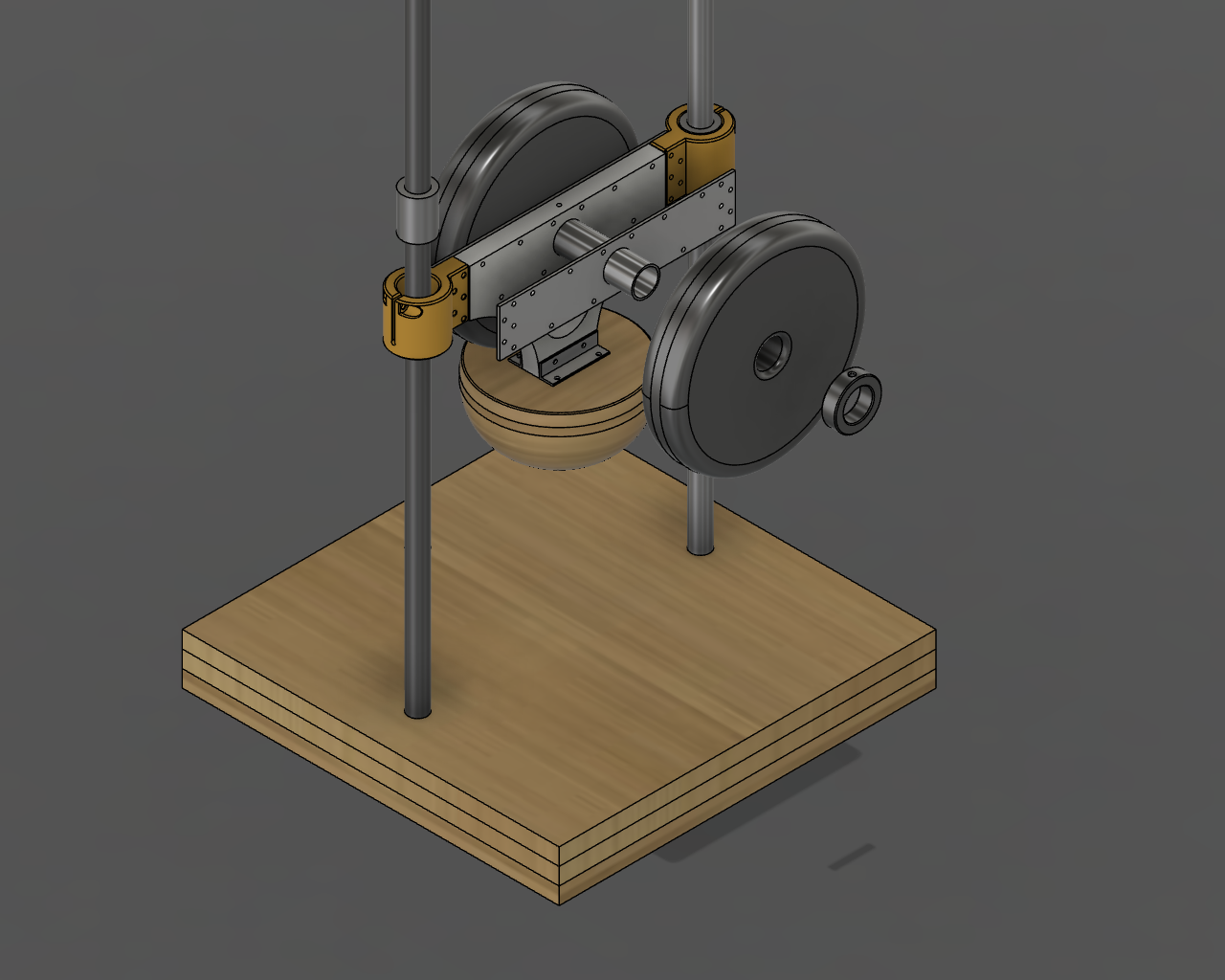

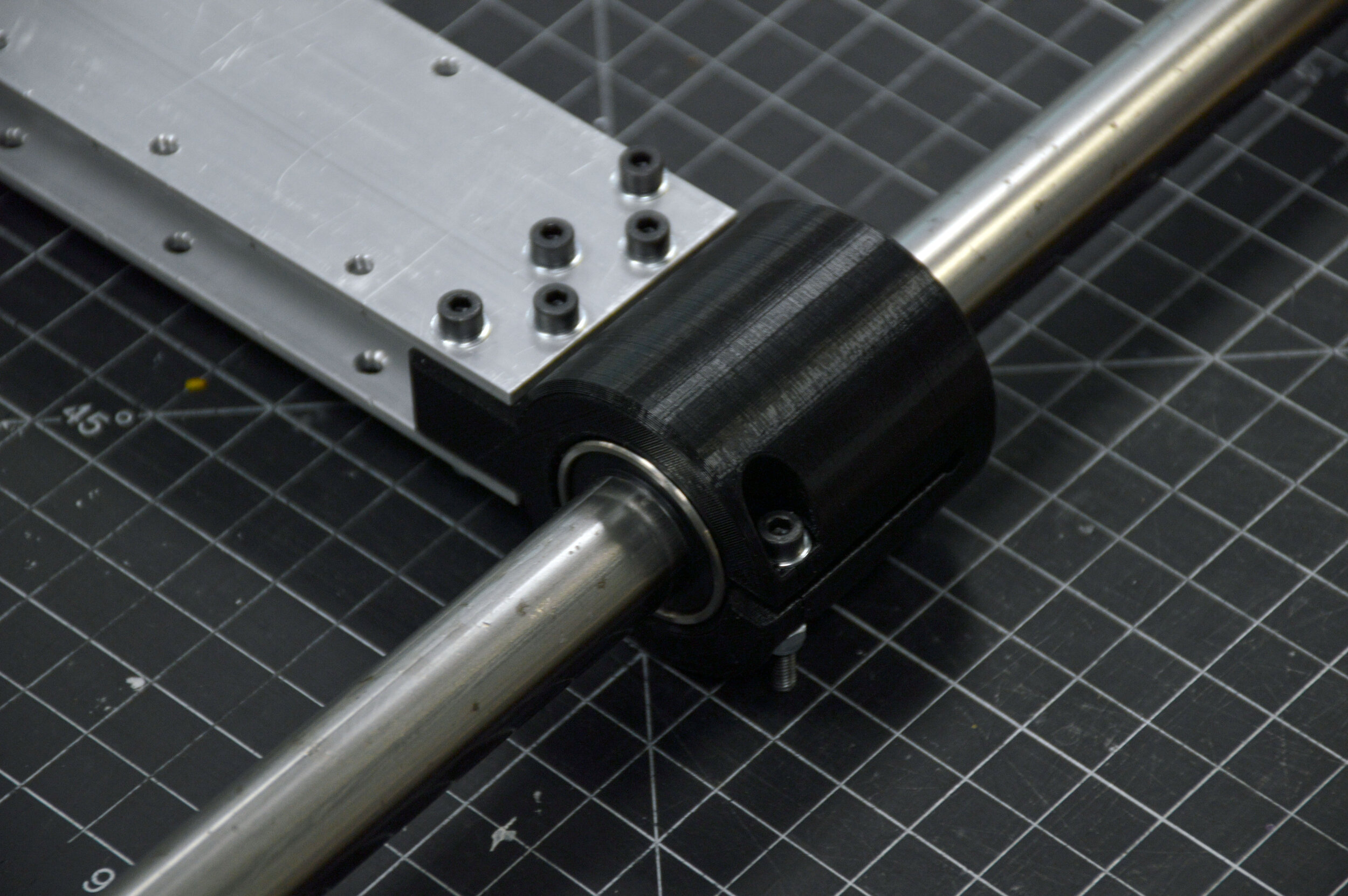

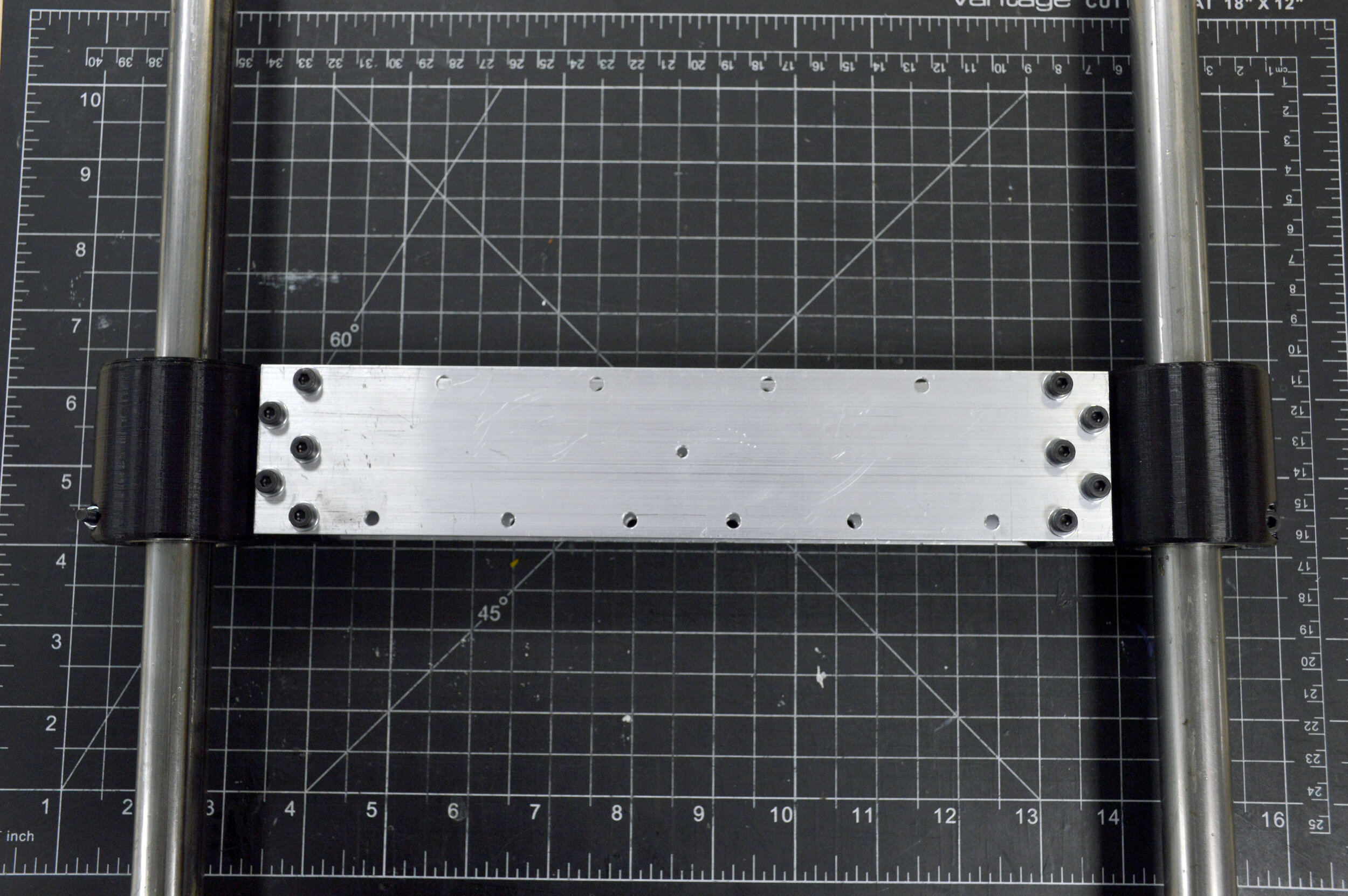

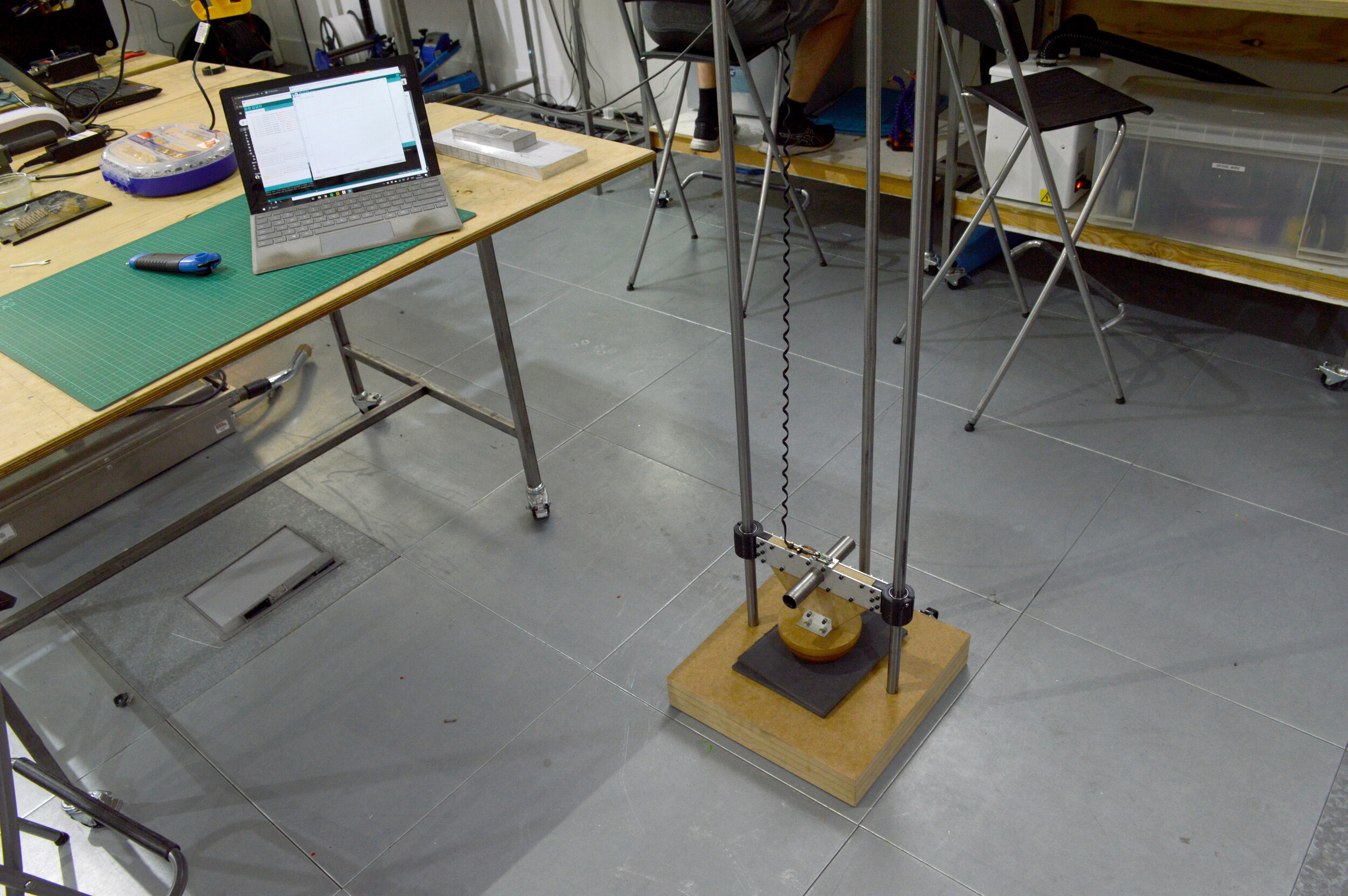

While I was exploring impact I needed to devise a way to validate my ideas, and drafted a Drop Test Rig that was within my skill set, available resources to construct, and got as close to the EN1078 Testing Standards. My drop test rig has a drop-distance of just over 1.5 meters and uses a high-range accelerometer to measure impact.

The biggest flaw of the rig in its current state is that the base is not heavy enough, and has a tendency to bounce when cycled under the full 5kg load. Due to resource constraints I would not be able to produce, store, and manage the recommended 500kg monolithic steel or concrete base as outlined in the EN1078 specifications. Another workaround is almost certainly possible.

Testing the action and function of the Drop Test Rig for measuring impacts up to 400G. [Sound Warning! Air Compressor goes off!]

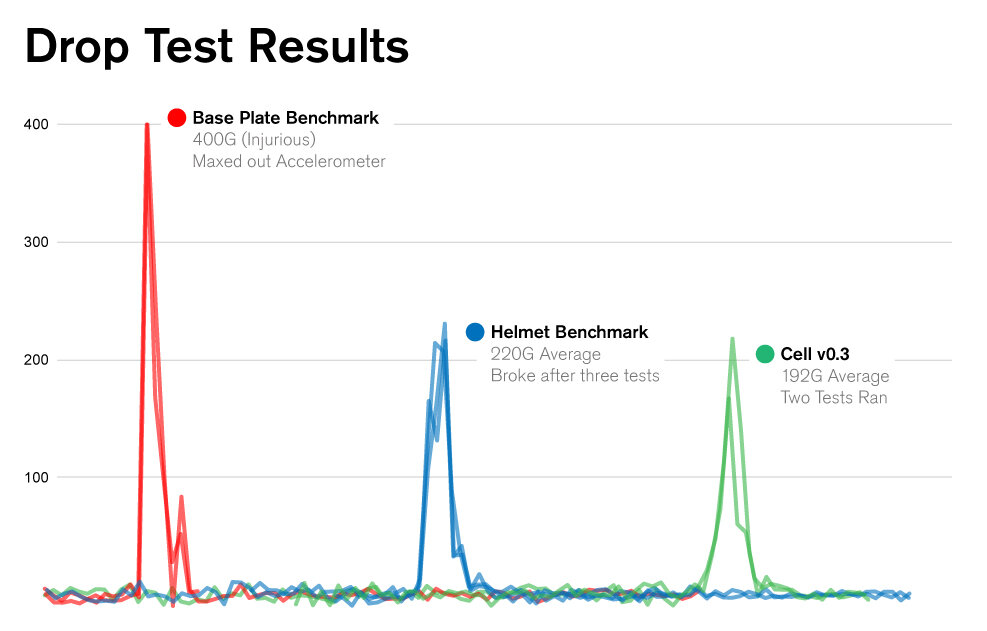

The testing cycle was programmed to record impact at 1ms intervals and dump the values into an array for maximum processing speed. Based off of a limited number of tests, Impact Cell v0.3 protected from an average of 8G more impact than a standard bicycle EPS helmet.