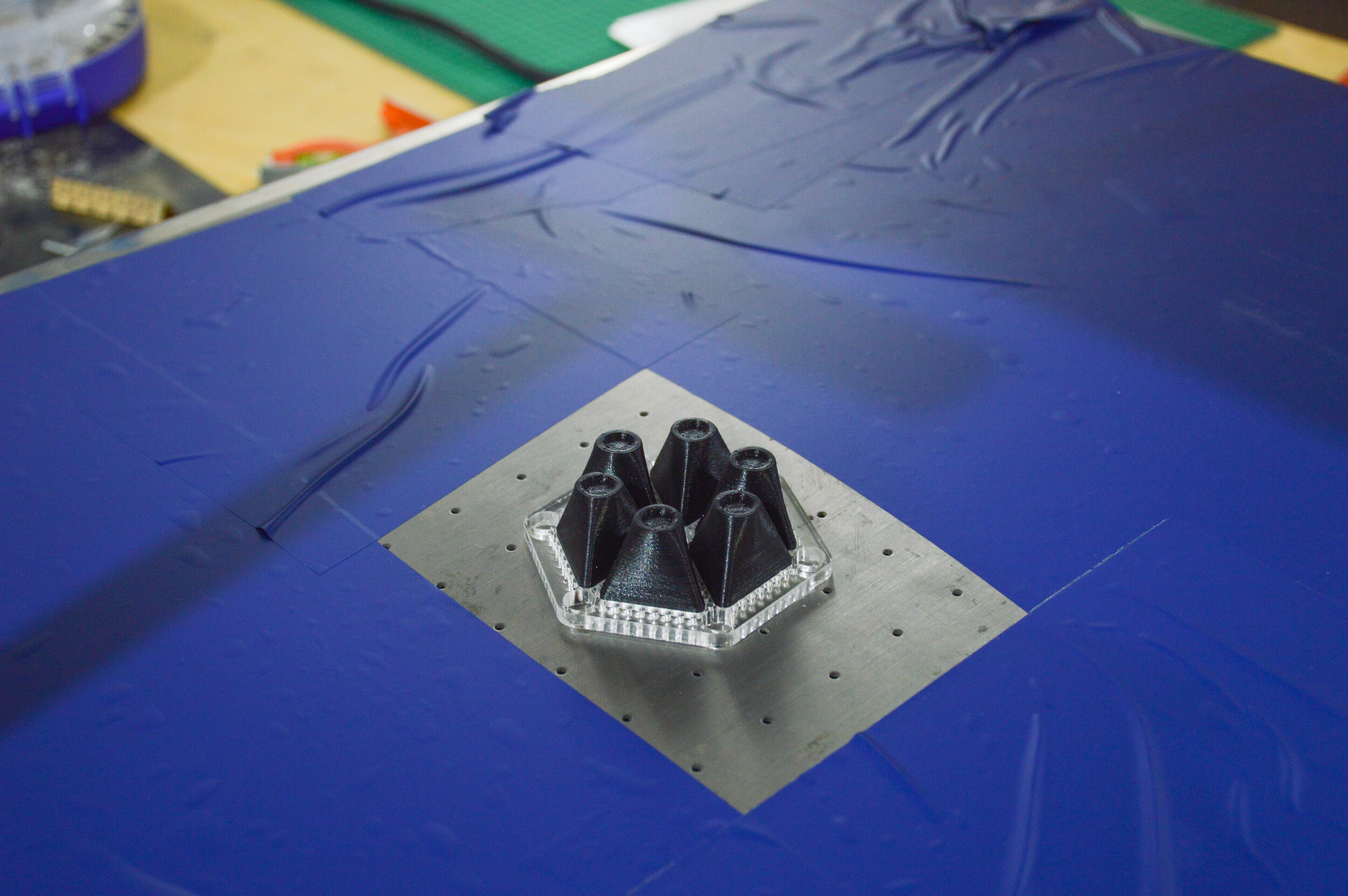

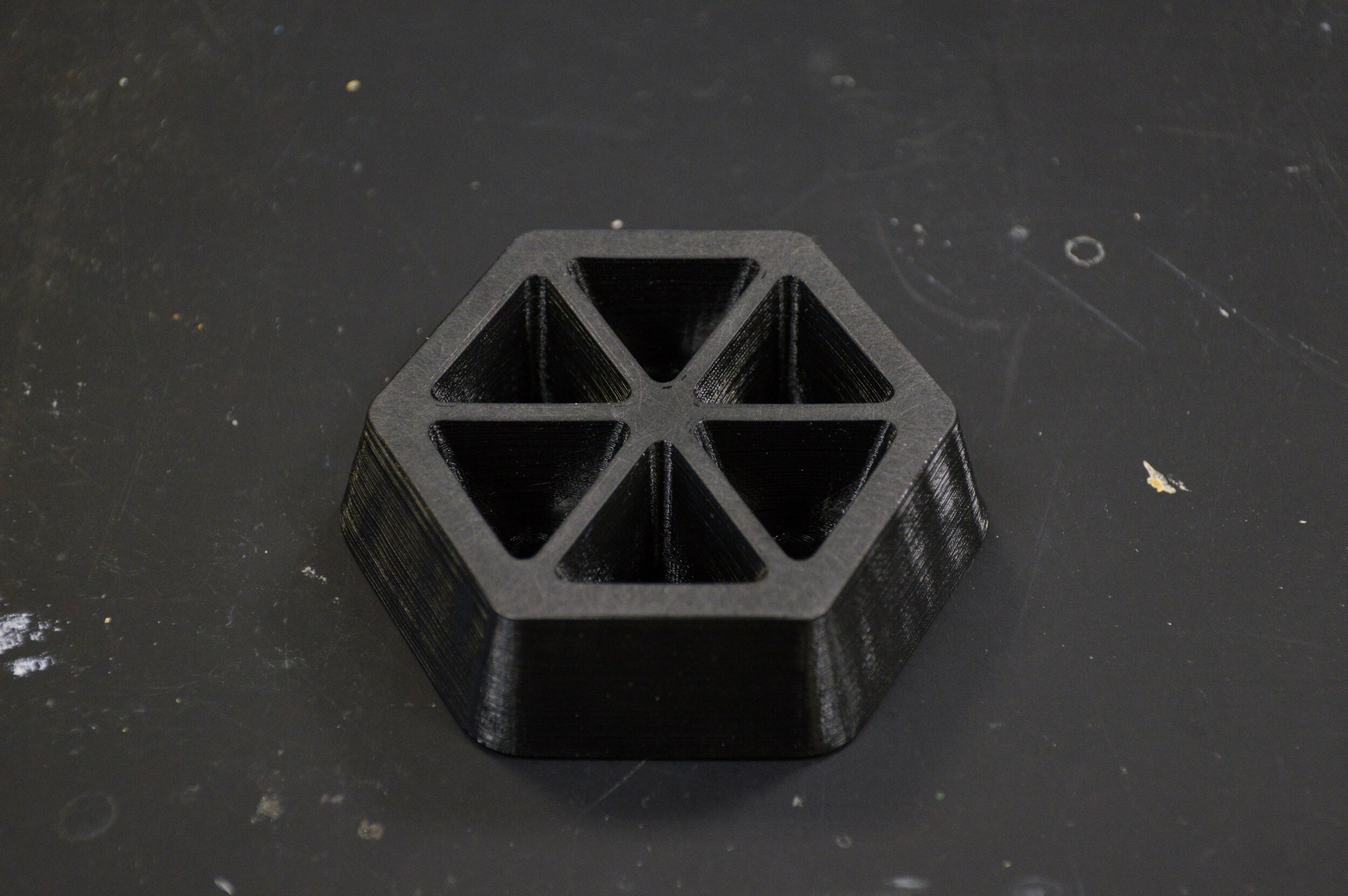

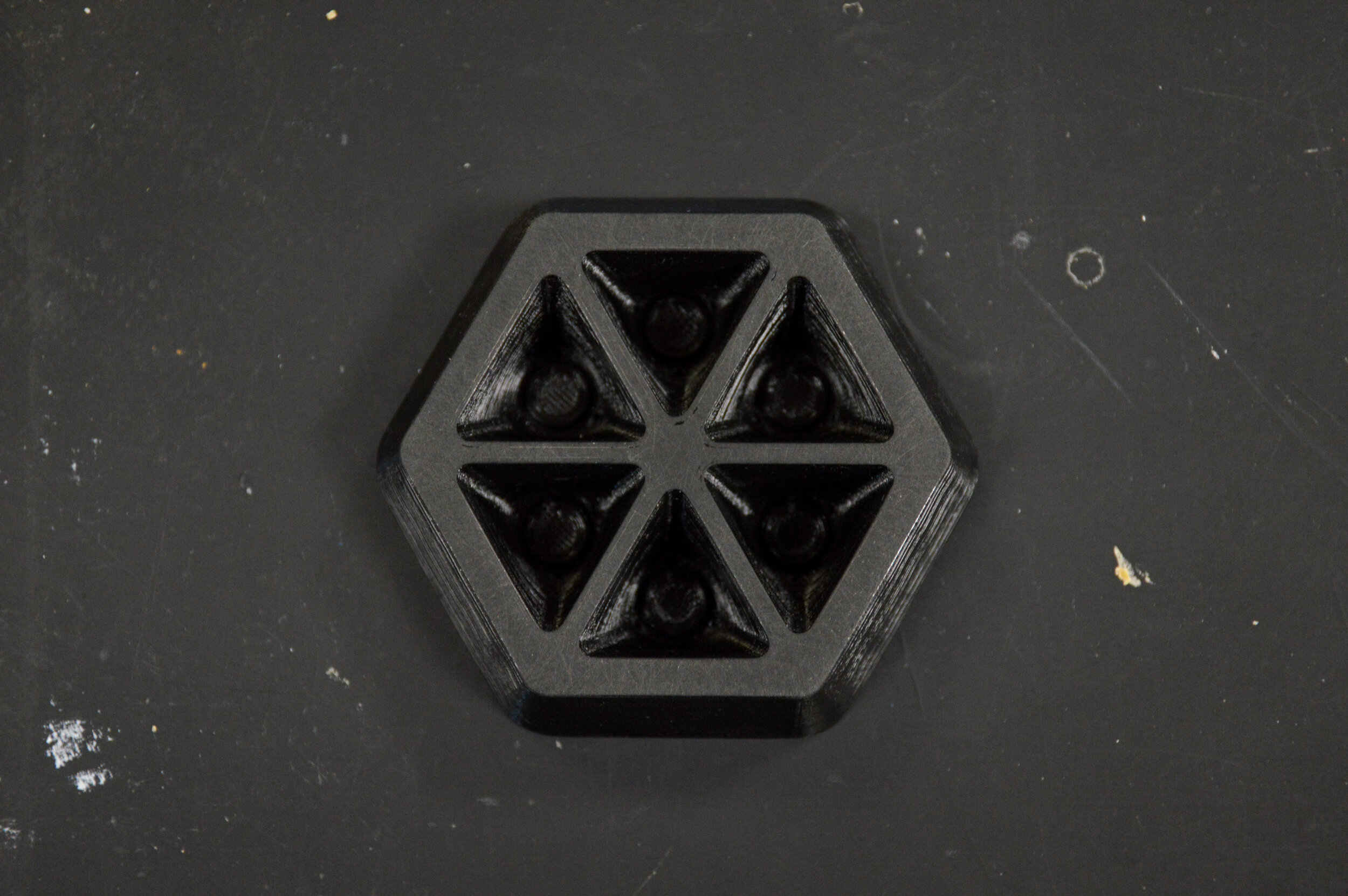

IMPACT CELL v0.3

2021 (Ongoing)

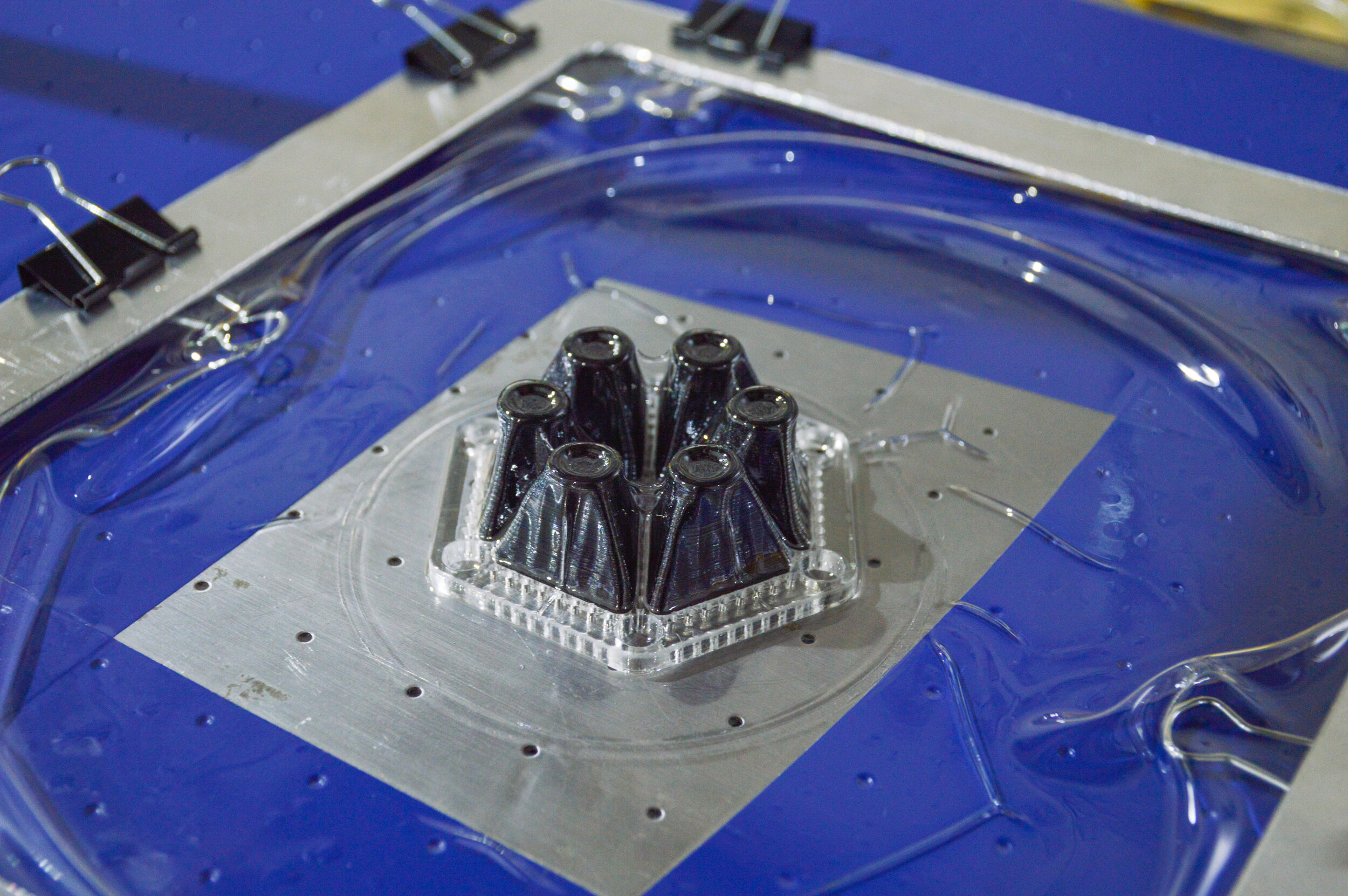

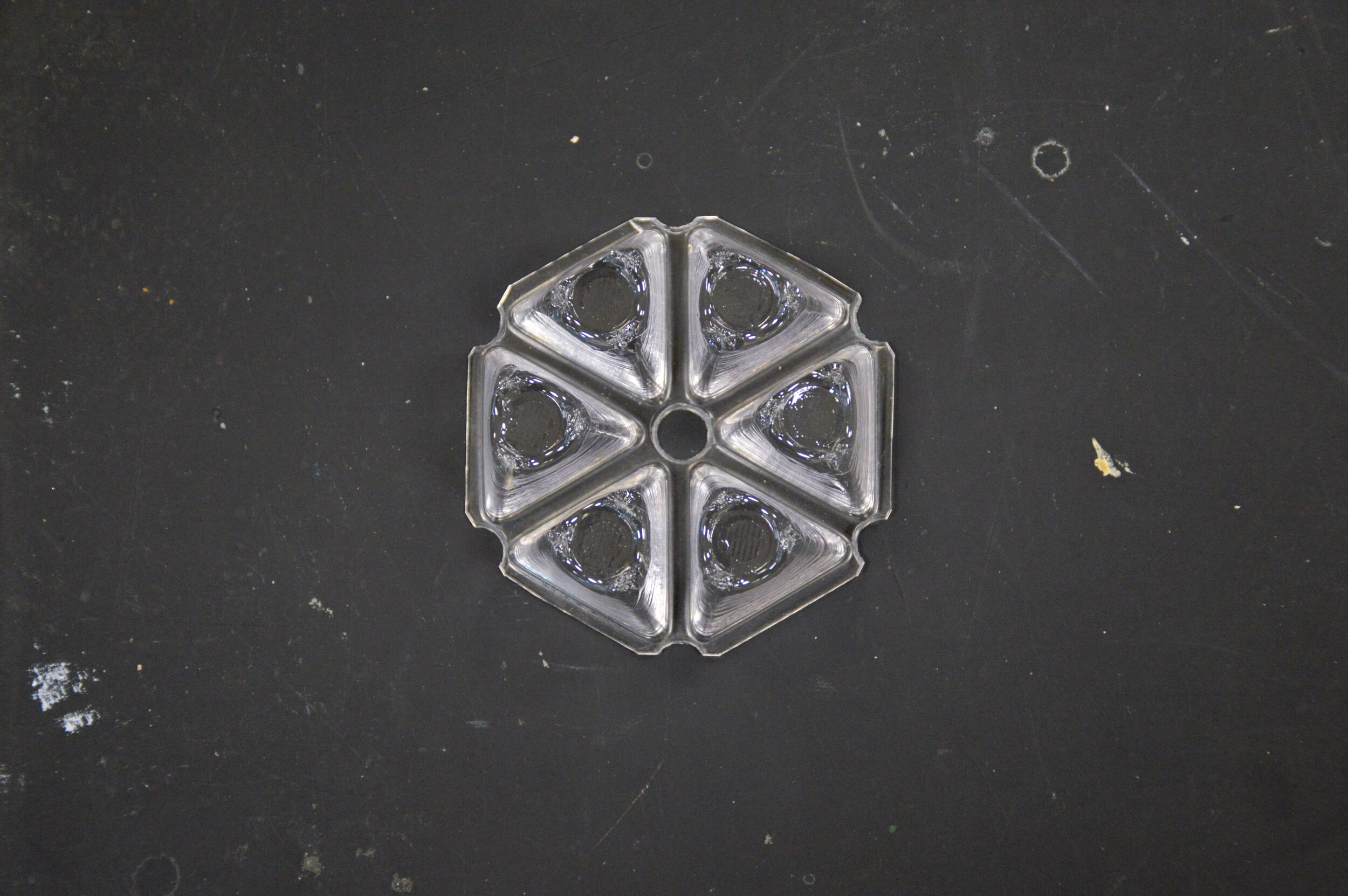

How could you take the Expanded Polystyrene (EPS) out of a helmet, while keeping it just as safe and manufacturable? This was my wicked question in developing the Impact Cell: a means of protecting from impact utilizing a process that is already a part of helmet production (namely thermoforming). While totally sustainable materials are certainly attractive to users they are difficult to implement on an Industrial scale.

This concept would require less production overhaul to implement, substantially reduce tooling and infrastructure costs for using EPS, and provide a morve visible indicator of when it is time to replace a helmet. Check out the Drop Test Rig for more details on the cell's impact profile.

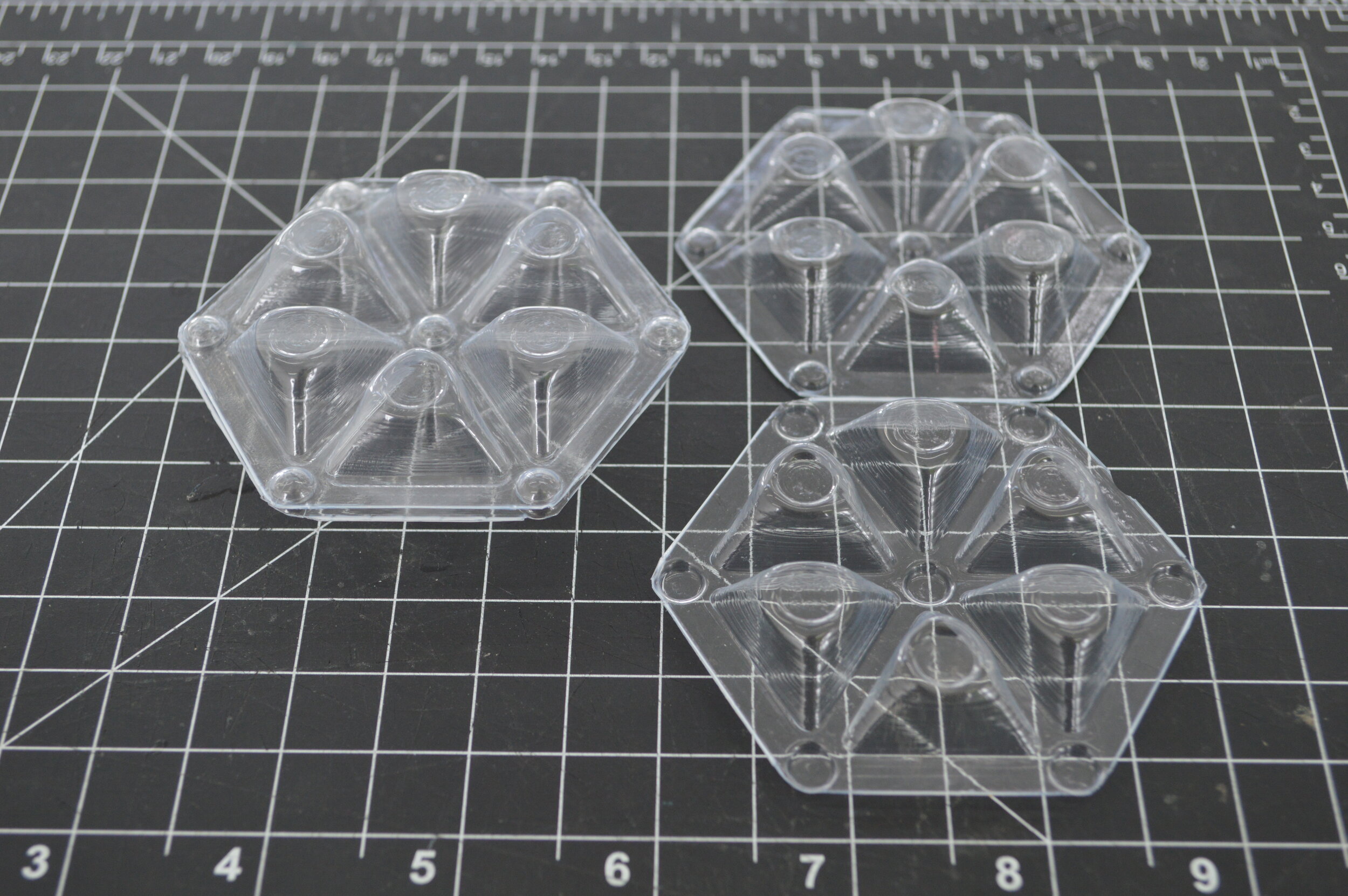

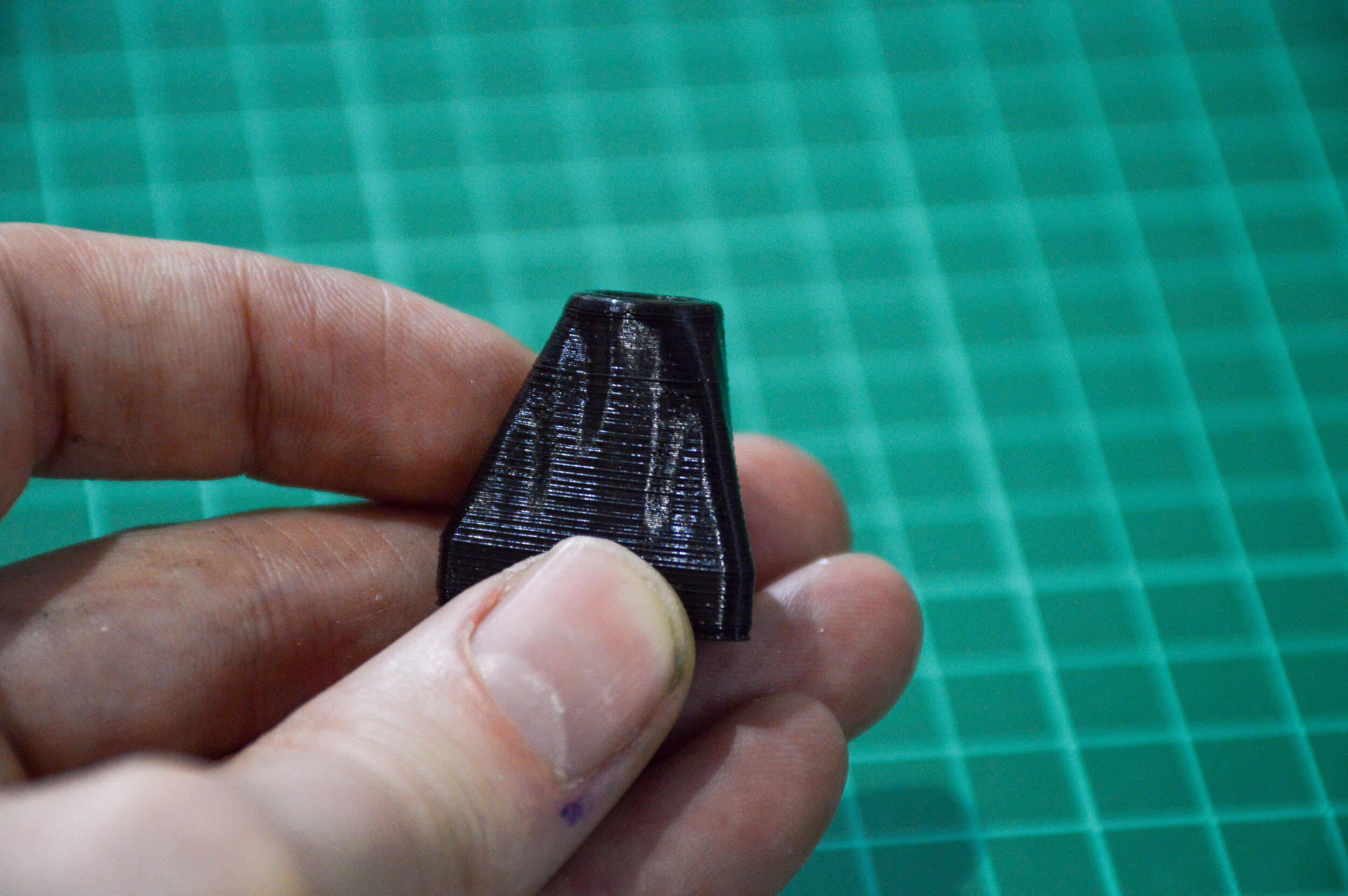

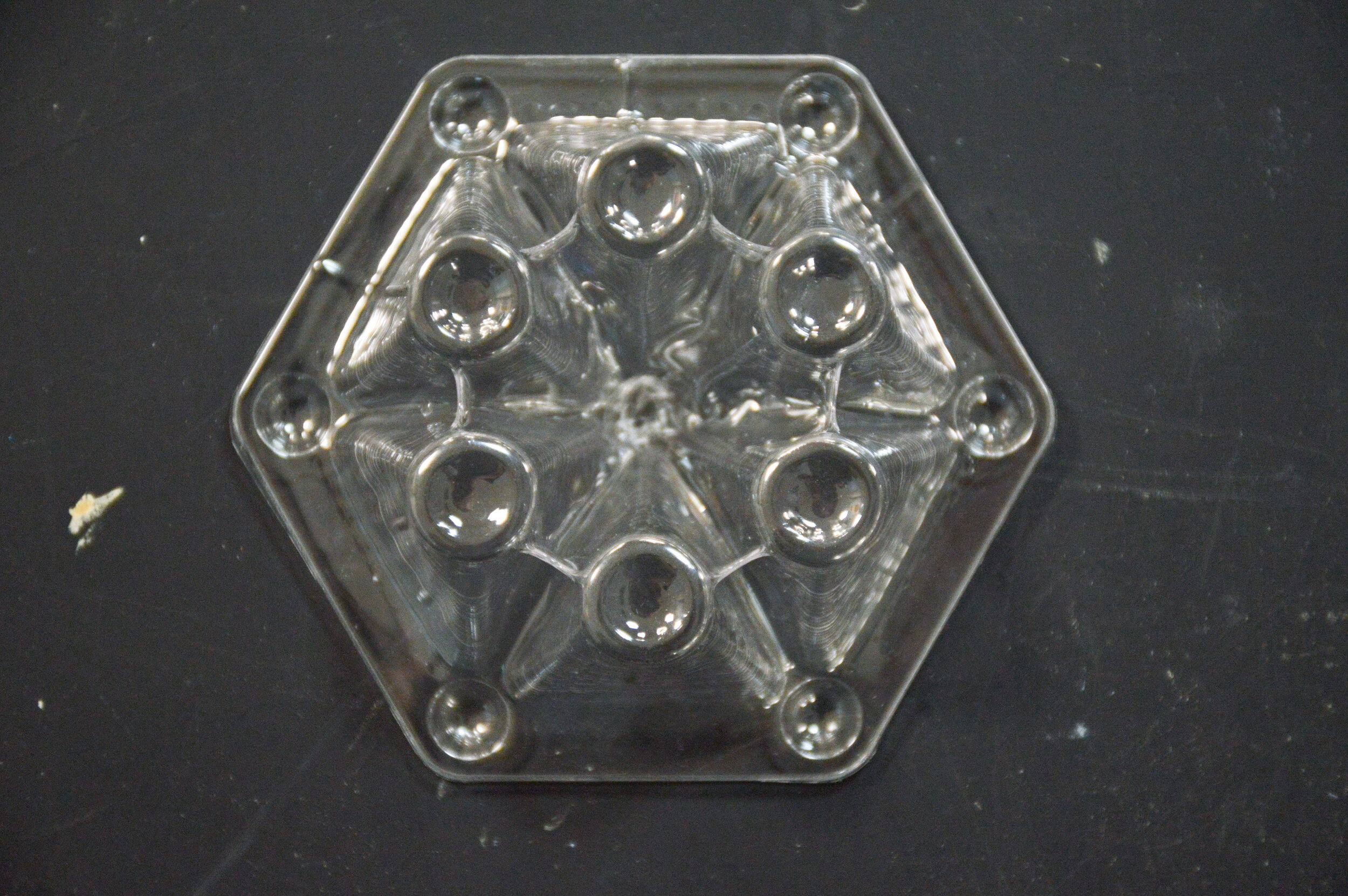

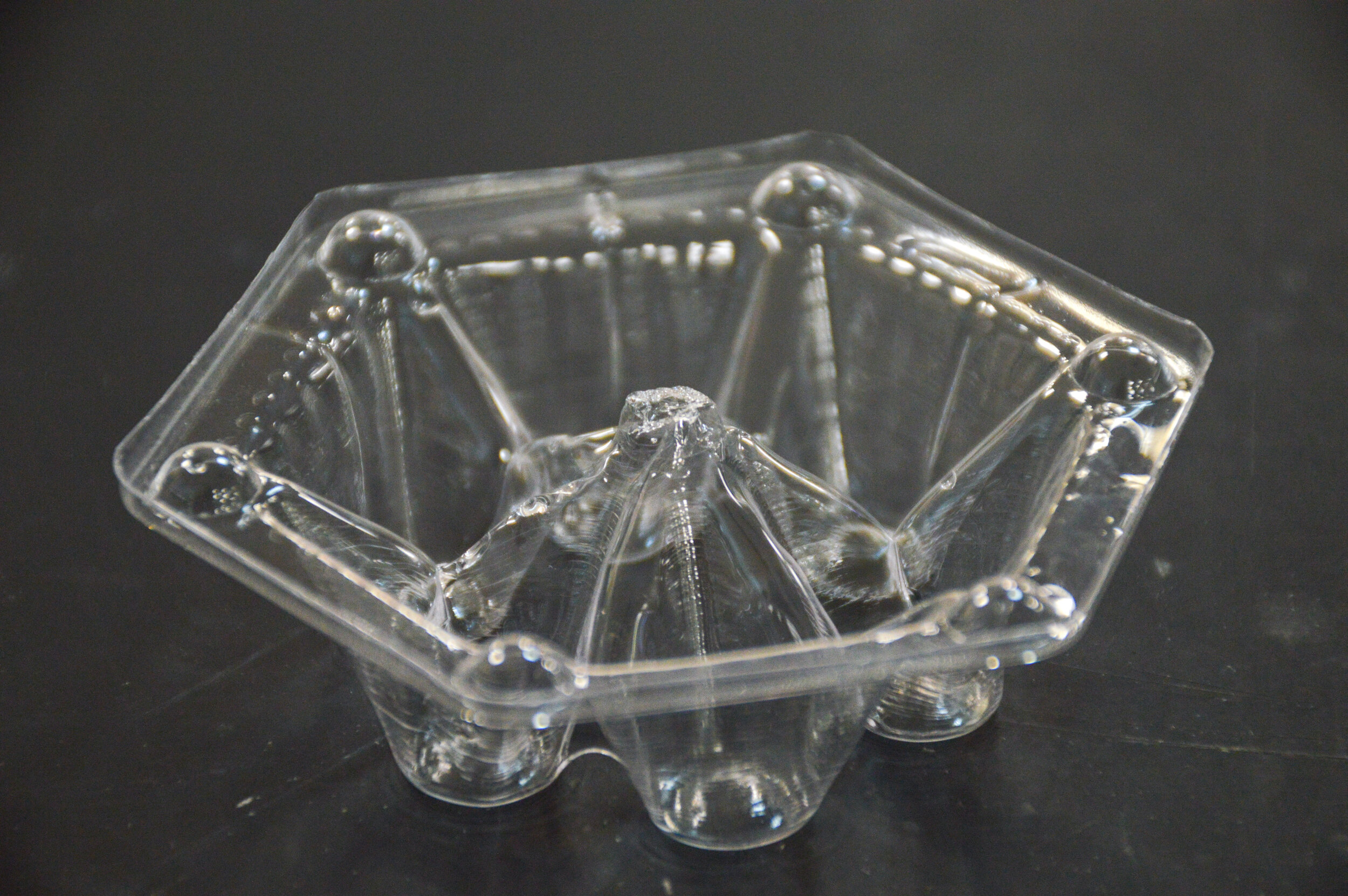

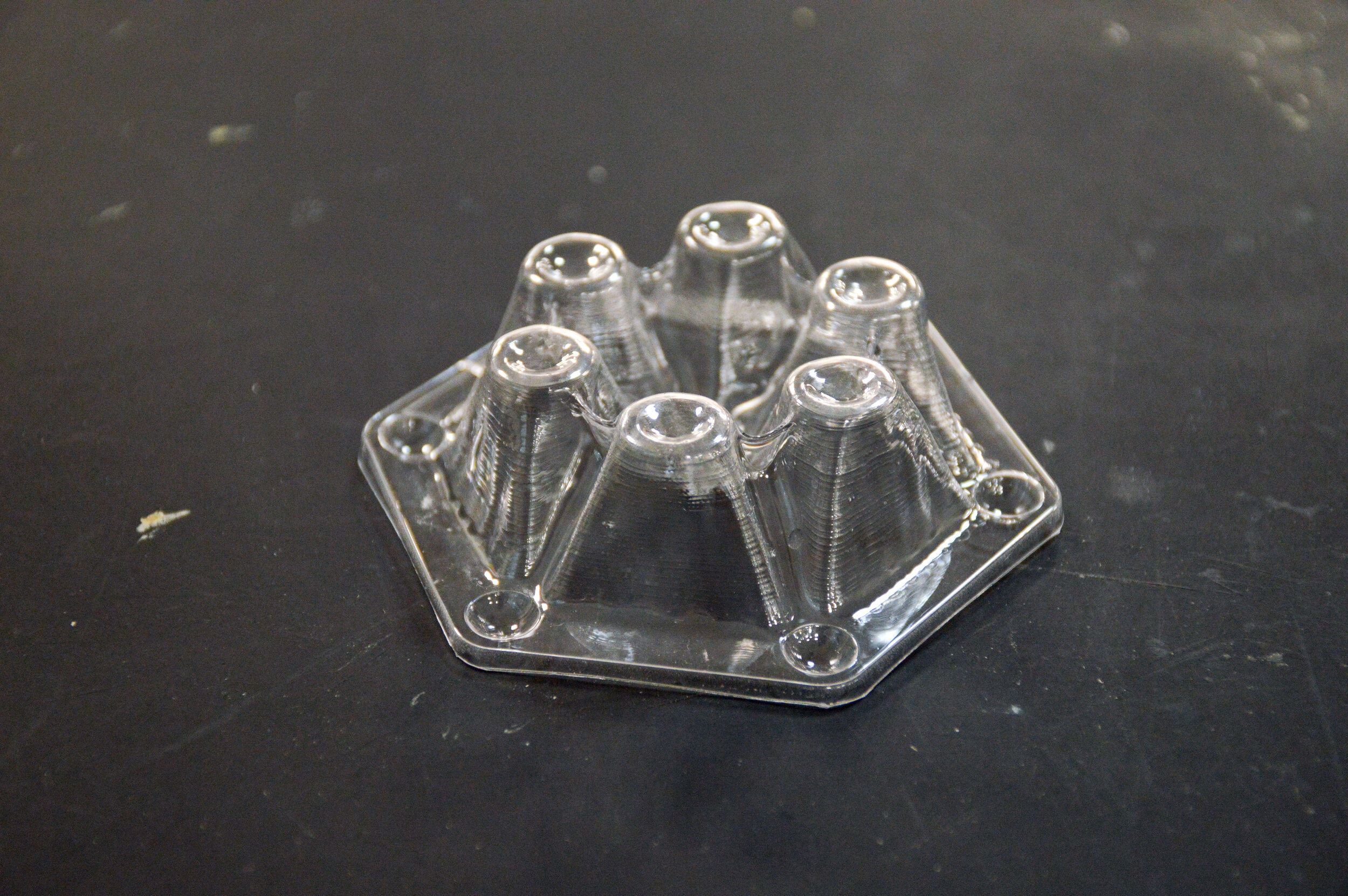

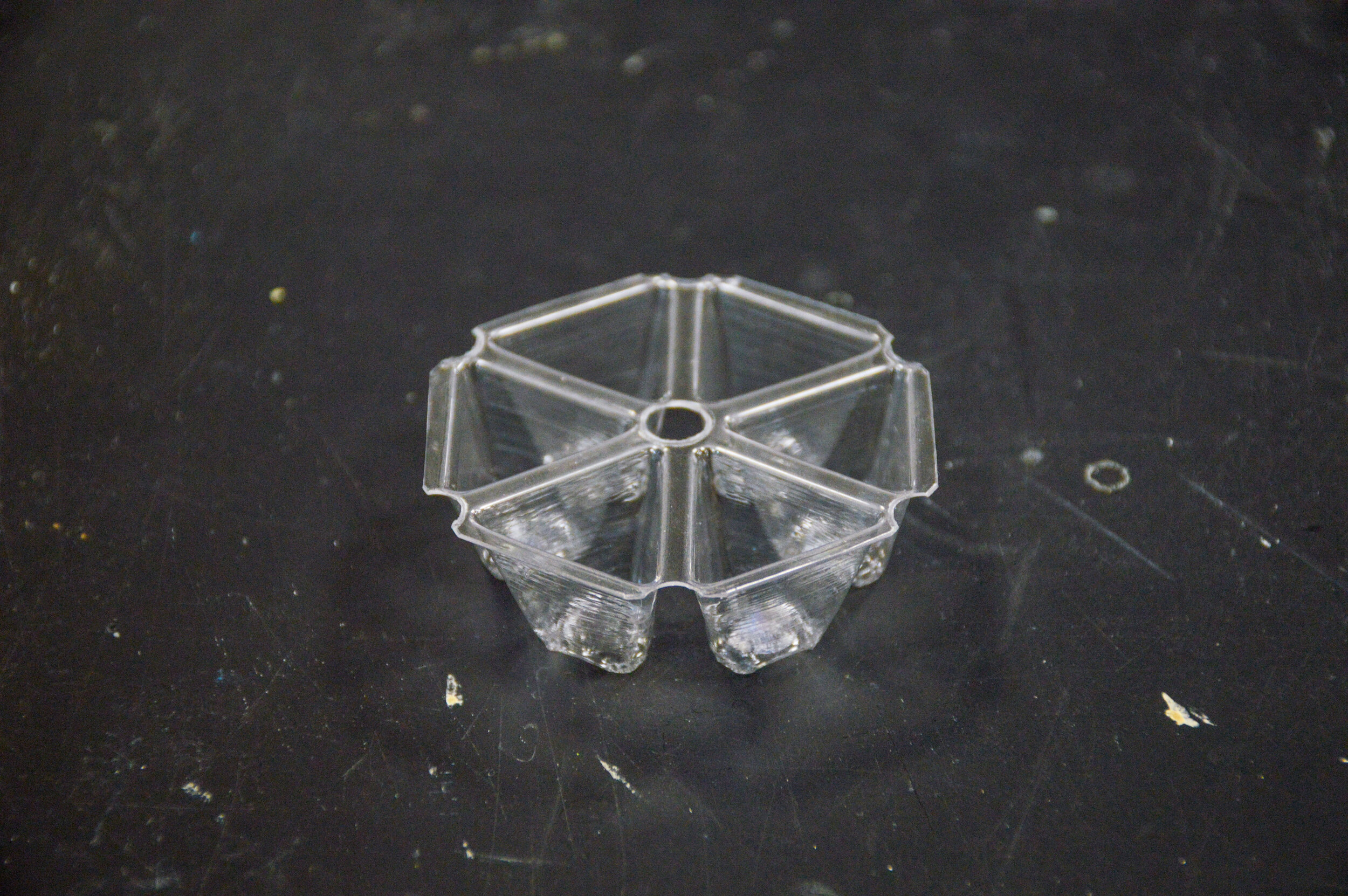

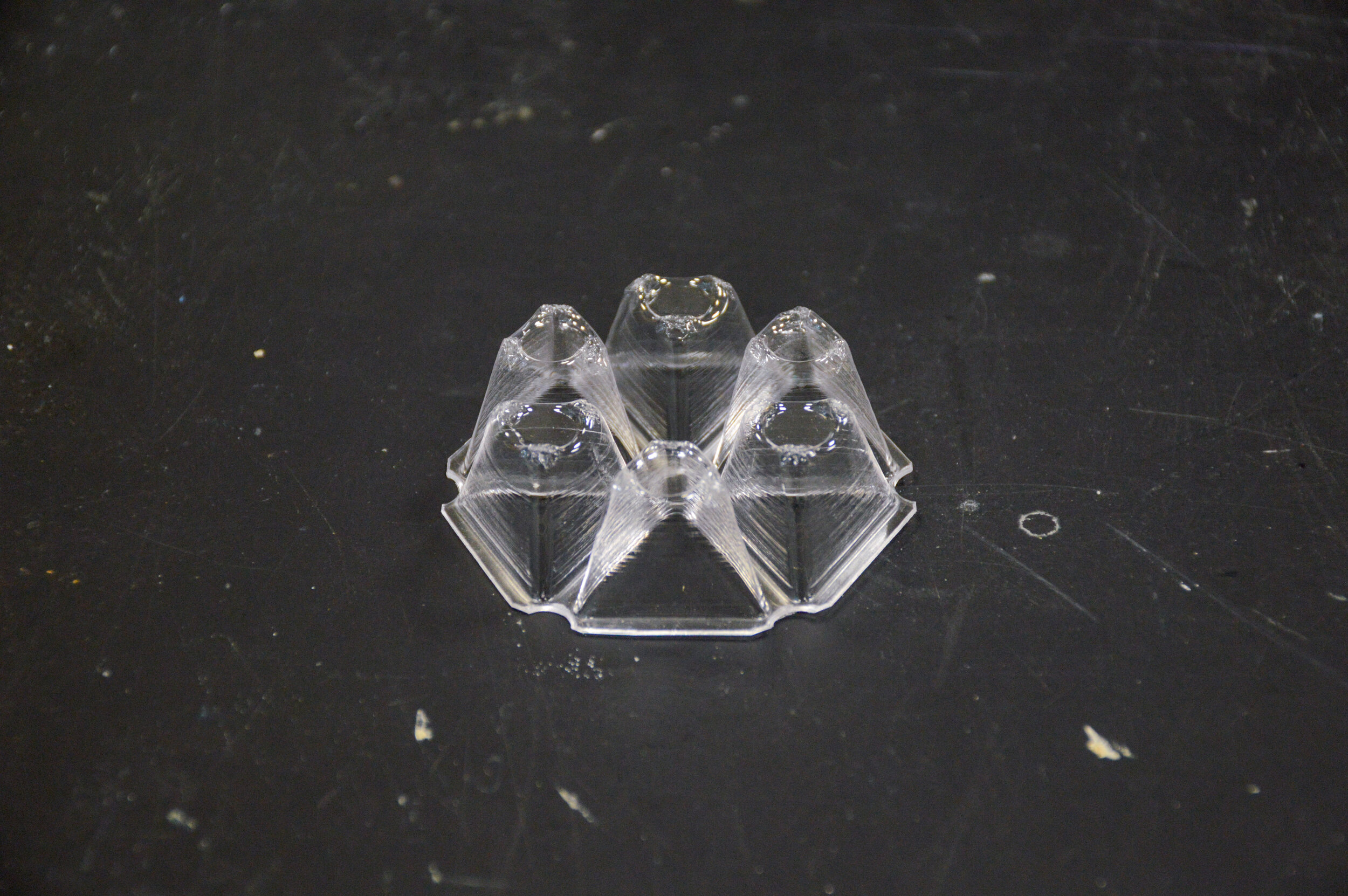

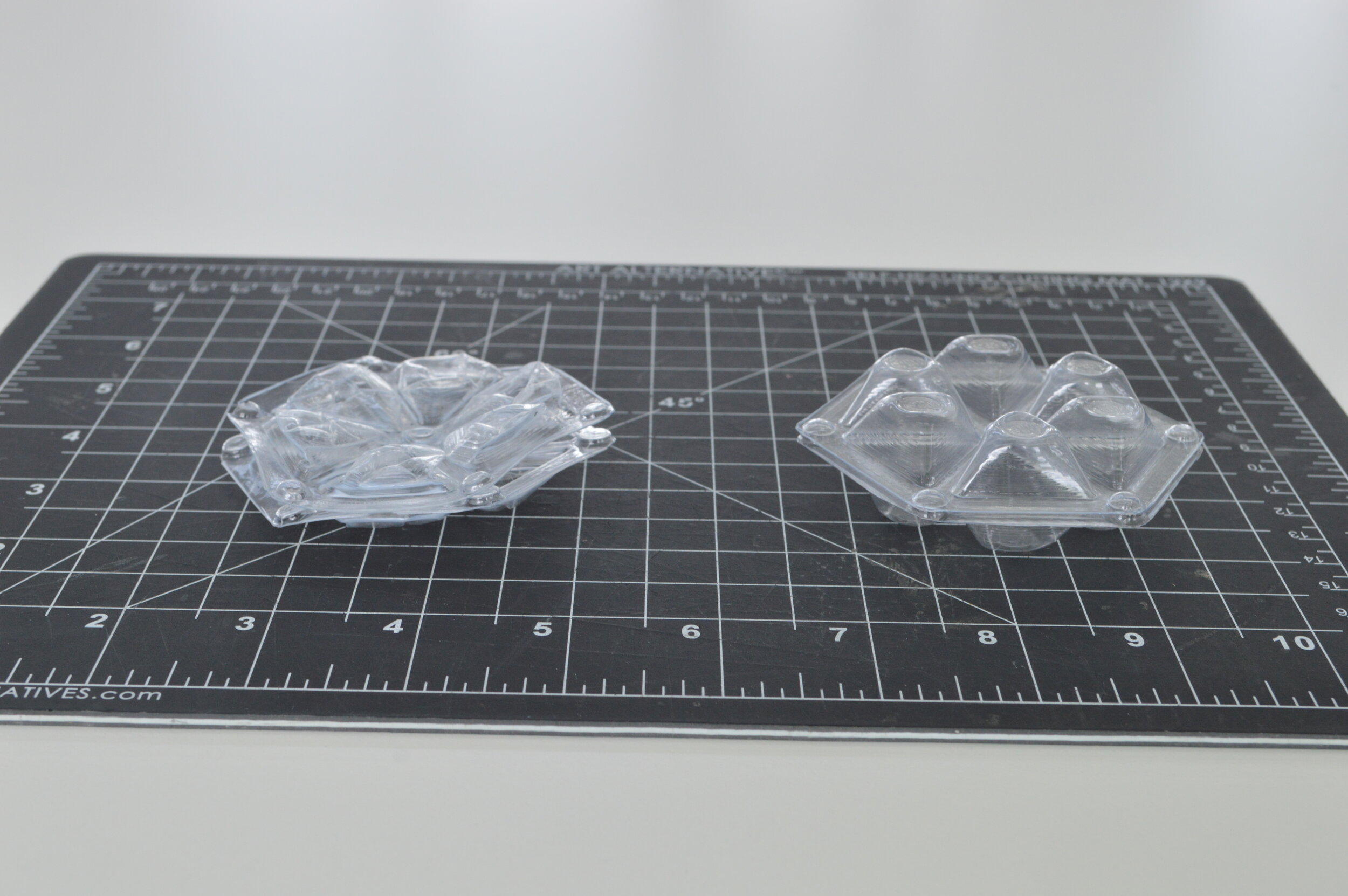

Iteration v0.3 utilized a dual-cell approach with a shorter draw depth to prevent the material from stretching too thin as in previous iterations. The two halves then snapped together with press-fit fixtures akin to clamshell packaging.